The mainstream optical device production process is a high-precision, high-tech manufacturing process involving a combination of multiple materials and processes. Optical devices are devices that can control, manipulate and utilize light, and are widely used in lasers, fiber-optic communications, cameras, microscopes and other fields. In the context of modern scientific and technological development, the production process of optical devices is also constantly innovating and improving to meet the growing market demand.

1. Design and simulation: The first step in the production of optical devices is to design and simulate the device. Designers use computer-aided design software to design and simulate the optical system based on customer needs and technical requirements to determine the structure, materials and parameters of the device.

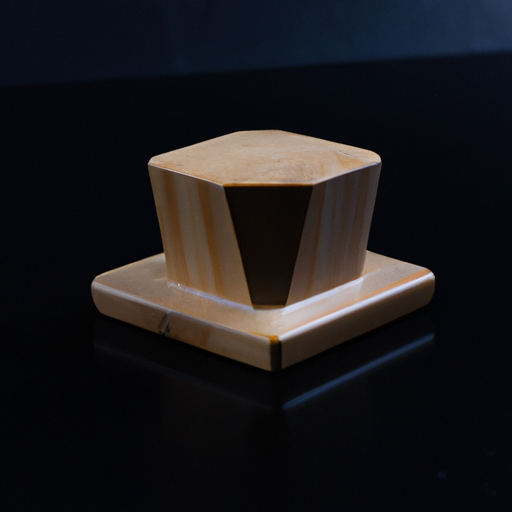

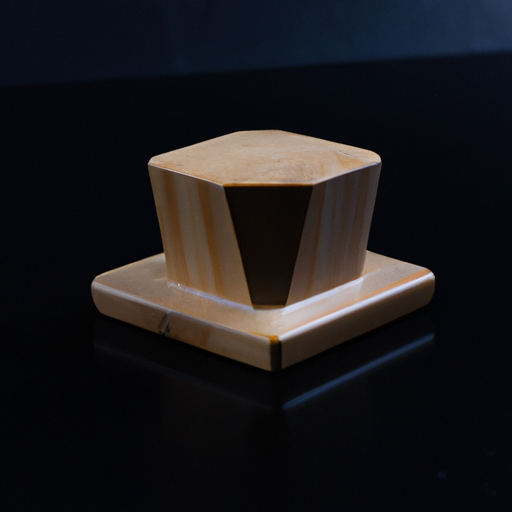

2. Material selection and processing: The performance and quality of optical devices are directly affected by the materials, so it is necessary to select appropriate materials during the production process. Commonly used optical materials include glass, crystal , plastic, etc. Material processing includes cutting, grinding, polishing and other processes to ensure the flatness and optical performance of the device surface.

3. Optical coating: The surface of optical devices usually needs to be treated with optical coating to improve transmittance, reflectivity and wear resistance. Optical coating usually uses vacuum evaporation, sputtering and other technologies to deposit metals, oxides, fluorides and other materials on the surface of the device.

4. Assembly and debugging: The assembly of optical devices is a key link, which requires the components to be assembled accurately, debugged and tested. During the assembly process, the optical performance and stability of the device must be guaranteed to ensure the normal operation of the device.

5. Inspection and quality control: Strict inspection and quality control are required during the production of optical devices to ensure that the performance and quality of the devices meet the requirements. Commonly used inspection methods include interferometry, diffraction, laser interferometry, etc., which are used to detect the surface morphology, optical performance and other parameters of the device.

In general, the production process of optical devices is a complex and precise manufacturing process that requires a combination of multiple materials and processes to ensure the performance and quality of the device. With the continuous development and progress of science and technology, the production process of optical devices is also constantly innovating and improving, providing more possibilities for the application of optical devices. It is hoped that the production process of optical devices in the future will be more efficient and precise, making greater contributions to the development of optical technology.

The mainstream optical device production process is a high-precision, high-tech manufacturing process involving a combination of multiple materials and processes. Optical devices are devices that can control, manipulate and utilize light, and are widely used in lasers, fiber-optic communications, cameras, microscopes and other fields. In the context of modern scientific and technological development, the production process of optical devices is also constantly innovating and improving to meet the growing market demand.

1. Design and simulation: The first step in the production of optical devices is to design and simulate the device. Designers use computer-aided design software to design and simulate the optical system based on customer needs and technical requirements to determine the structure, materials and parameters of the device.

2. Material selection and processing: The performance and quality of optical devices are directly affected by the materials, so it is necessary to select appropriate materials during the production process. Commonly used optical materials include glass, crystal , plastic, etc. Material processing includes cutting, grinding, polishing and other processes to ensure the flatness and optical performance of the device surface.

3. Optical coating: The surface of optical devices usually needs to be treated with optical coating to improve transmittance, reflectivity and wear resistance. Optical coating usually uses vacuum evaporation, sputtering and other technologies to deposit metals, oxides, fluorides and other materials on the surface of the device.

4. Assembly and debugging: The assembly of optical devices is a key link, which requires the components to be assembled accurately, debugged and tested. During the assembly process, the optical performance and stability of the device must be guaranteed to ensure the normal operation of the device.

5. Inspection and quality control: Strict inspection and quality control are required during the production of optical devices to ensure that the performance and quality of the devices meet the requirements. Commonly used inspection methods include interferometry, diffraction, laser interferometry, etc., which are used to detect the surface morphology, optical performance and other parameters of the device.

In general, the production process of optical devices is a complex and precise manufacturing process that requires a combination of multiple materials and processes to ensure the performance and quality of the device. With the continuous development and progress of science and technology, the production process of optical devices is also constantly innovating and improving, providing more possibilities for the application of optical devices. It is hoped that the production process of optical devices in the future will be more efficient and precise, making greater contributions to the development of optical technology.