A power transformer is an electrical device that converts AC electrical energy into the desired voltage, widely used in various electronic devices. In the production of power transformers, a series of manufacturing processes are required to ensure product quality and performance. Below are the common production processes of power transformers.

Next is material procurement. Various materials such as iron core, insulation materials, conductors, etc., are required in the production of power transformers. Manufacturers need to select high-quality material suppliers to ensure that the material quality meets the requirements. Strict quality inspections are required during the material procurement process to ensure product quality.

The third step is iron core processing. The iron core is an important component of the power transformer, directly affecting the product's performance. Iron core processing includes cutting, straightening, stacking, and other processes that require precision equipment and technology. It is important to maintain the flatness and accuracy of the iron core during the processing to ensure stable product performance.

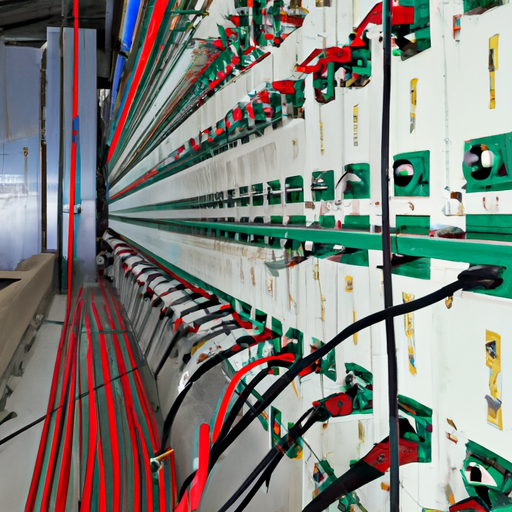

The fourth step is winding. Winding is a key process in the production of power transformers, directly affecting the product's electrical performance. During the winding process, conductors are wound around the iron core according to the design requirements to form windings. Insulation and connection of the conductors need to be carefully considered during the winding process to ensure product safety and reliability.

The fifth step is insulation treatment. Insulation treatment is an important process to ensure the safe and reliable operation of the power transformer. Insulation treatment includes processes such as insulation varnish coating and insulation paper wrapping to improve the product's insulation level and withstand voltage capability.

Finally, assembly and testing. Assembly involves assembling various components to form a complete power transformer product. During assembly, attention needs to be paid to the connection and fixation of components to ensure product stability and reliability. Testing involves performance testing and quality inspection of the product to ensure that it meets design requirements and standards.

In summary, the production of power transformers requires a series of manufacturing processes including design, material procurement, iron core processing, winding, insulation treatment, assembly, and testing. Each process needs to be strictly controlled to ensure product quality and performance. Only through scientific production processes can high-quality power transformer products be produced to meet customer needs and requirements.

A power transformer is an electrical device that converts AC electrical energy into the desired voltage, widely used in various electronic devices. In the production of power transformers, a series of manufacturing processes are required to ensure product quality and performance. Below are the common production processes of power transformers.

Next is material procurement. Various materials such as iron core, insulation materials, conductors, etc., are required in the production of power transformers. Manufacturers need to select high-quality material suppliers to ensure that the material quality meets the requirements. Strict quality inspections are required during the material procurement process to ensure product quality.

The third step is iron core processing. The iron core is an important component of the power transformer, directly affecting the product's performance. Iron core processing includes cutting, straightening, stacking, and other processes that require precision equipment and technology. It is important to maintain the flatness and accuracy of the iron core during the processing to ensure stable product performance.

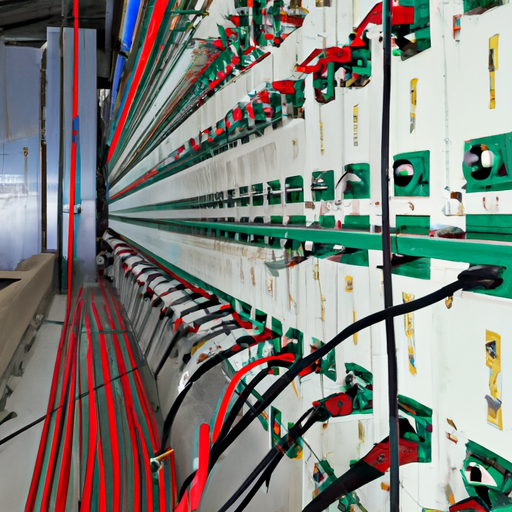

The fourth step is winding. Winding is a key process in the production of power transformers, directly affecting the product's electrical performance. During the winding process, conductors are wound around the iron core according to the design requirements to form windings. Insulation and connection of the conductors need to be carefully considered during the winding process to ensure product safety and reliability.

The fifth step is insulation treatment. Insulation treatment is an important process to ensure the safe and reliable operation of the power transformer. Insulation treatment includes processes such as insulation varnish coating and insulation paper wrapping to improve the product's insulation level and withstand voltage capability.

Finally, assembly and testing. Assembly involves assembling various components to form a complete power transformer product. During assembly, attention needs to be paid to the connection and fixation of components to ensure product stability and reliability. Testing involves performance testing and quality inspection of the product to ensure that it meets design requirements and standards.

In summary, the production of power transformers requires a series of manufacturing processes including design, material procurement, iron core processing, winding, insulation treatment, assembly, and testing. Each process needs to be strictly controlled to ensure product quality and performance. Only through scientific production processes can high-quality power transformer products be produced to meet customer needs and requirements.