Title: Bridge Rectifier: A Crucial Component in Power Electronics

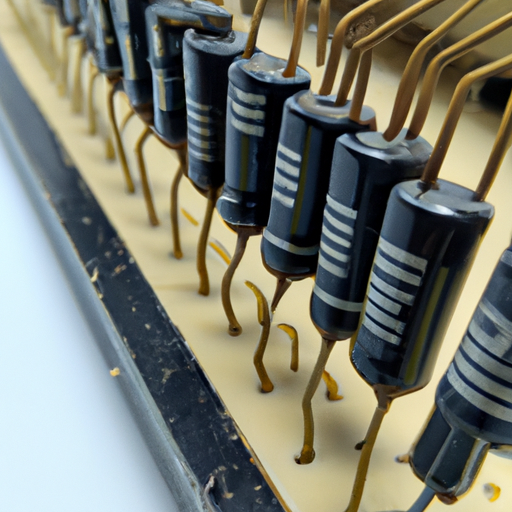

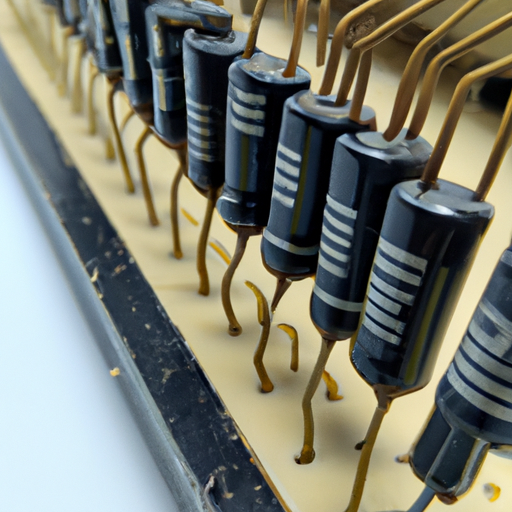

I. Working Principle of Bridge Rectifiers (200 words) Bridge rectifiers are based on the principle of rectification, which involves converting AC voltage into pulsating DC voltage. The bridge rectifier consists of four diodes arranged in a bridge configuration, forming a full-wave rectifier circuit. When the AC input voltage is applied, the diodes conduct alternately, allowing current to flow in only one direction, resulting in a rectified output.

II. Types of Bridge Rectifiers (250 words) 1. Single-phase Bridge Rectifier: This type of bridge rectifier is commonly used in low-power applications and consists of four diodes connected in a bridge configuration. 2. Three-phase Bridge Rectifier: Suitable for high-power applications, the three-phase bridge rectifier employs six diodes to rectify three-phase AC voltage.

III. Applications of Bridge Rectifiers (300 words) 1. Power Supplies: Bridge rectifiers are extensively used in power supplies to convert AC voltage from the mains into DC voltage, ensuring a stable and reliable power source for various electronic devices. 2. Battery Chargers: Bridge rectifiers are employed in battery chargers to convert AC voltage into DC voltage for charging batteries efficiently. 3. Motor Drives: Bridge rectifiers are crucial components in motor drives, converting AC voltage into DC voltage to control the speed and direction of motors. 4. Welding Machines: Bridge rectifiers are utilized in welding machines to convert AC voltage into DC voltage for welding operations. 5. Uninterruptible Power Supplies (UPS): Bridge rectifiers are integral to UPS systems, converting AC voltage into DC voltage to charge the backup batteries and provide uninterrupted power during power outages.

IV. Advantages of Bridge Rectifiers (200 words) 1. Full-Wave Rectification: Bridge rectifiers provide full-wave rectification, resulting in a smoother and more efficient DC output compared to half-wave rectifiers. 2. Compact Size: Bridge rectifiers are compact in size, making them suitable for various applications where space is limited. 3. High Efficiency: Bridge rectifiers offer high efficiency in converting AC to DC voltage, minimizing power losses and maximizing energy utilization. 4. Cost-Effective: Bridge rectifiers are cost-effective solutions due to their simple design and widespread availability.

V. Limitations of Bridge Rectifiers (150 words) 1. Voltage Drop: Bridge rectifiers have a voltage drop across the diodes, resulting in a slight loss of voltage during the rectification process. 2. Heat Dissipation: Bridge rectifiers generate heat during operation, requiring proper heat sinking or cooling mechanisms to prevent overheating. 3. Non-Isolation: Bridge rectifiers do not provide electrical isolation between the input and output, necessitating additional isolation components in certain applications.

Conclusion (100 words) Bridge rectifiers are indispensable components in power electronics, enabling the conversion of AC voltage into DC voltage for a wide range of applications. Their compact size, high efficiency, and cost-effectiveness make them a preferred choice in various industries. Understanding the working principles, types, applications, advantages, and limitations of bridge rectifiers is crucial for engineers and enthusiasts working with power electronics.

Title: Bridge Rectifier: A Crucial Component in Power Electronics

I. Working Principle of Bridge Rectifiers (200 words) Bridge rectifiers are based on the principle of rectification, which involves converting AC voltage into pulsating DC voltage. The bridge rectifier consists of four diodes arranged in a bridge configuration, forming a full-wave rectifier circuit. When the AC input voltage is applied, the diodes conduct alternately, allowing current to flow in only one direction, resulting in a rectified output.

II. Types of Bridge Rectifiers (250 words) 1. Single-phase Bridge Rectifier: This type of bridge rectifier is commonly used in low-power applications and consists of four diodes connected in a bridge configuration. 2. Three-phase Bridge Rectifier: Suitable for high-power applications, the three-phase bridge rectifier employs six diodes to rectify three-phase AC voltage.

III. Applications of Bridge Rectifiers (300 words) 1. Power Supplies: Bridge rectifiers are extensively used in power supplies to convert AC voltage from the mains into DC voltage, ensuring a stable and reliable power source for various electronic devices. 2. Battery Chargers: Bridge rectifiers are employed in battery chargers to convert AC voltage into DC voltage for charging batteries efficiently. 3. Motor Drives: Bridge rectifiers are crucial components in motor drives, converting AC voltage into DC voltage to control the speed and direction of motors. 4. Welding Machines: Bridge rectifiers are utilized in welding machines to convert AC voltage into DC voltage for welding operations. 5. Uninterruptible Power Supplies (UPS): Bridge rectifiers are integral to UPS systems, converting AC voltage into DC voltage to charge the backup batteries and provide uninterrupted power during power outages.

IV. Advantages of Bridge Rectifiers (200 words) 1. Full-Wave Rectification: Bridge rectifiers provide full-wave rectification, resulting in a smoother and more efficient DC output compared to half-wave rectifiers. 2. Compact Size: Bridge rectifiers are compact in size, making them suitable for various applications where space is limited. 3. High Efficiency: Bridge rectifiers offer high efficiency in converting AC to DC voltage, minimizing power losses and maximizing energy utilization. 4. Cost-Effective: Bridge rectifiers are cost-effective solutions due to their simple design and widespread availability.

V. Limitations of Bridge Rectifiers (150 words) 1. Voltage Drop: Bridge rectifiers have a voltage drop across the diodes, resulting in a slight loss of voltage during the rectification process. 2. Heat Dissipation: Bridge rectifiers generate heat during operation, requiring proper heat sinking or cooling mechanisms to prevent overheating. 3. Non-Isolation: Bridge rectifiers do not provide electrical isolation between the input and output, necessitating additional isolation components in certain applications.

Conclusion (100 words) Bridge rectifiers are indispensable components in power electronics, enabling the conversion of AC voltage into DC voltage for a wide range of applications. Their compact size, high efficiency, and cost-effectiveness make them a preferred choice in various industries. Understanding the working principles, types, applications, advantages, and limitations of bridge rectifiers is crucial for engineers and enthusiasts working with power electronics.