Title: Emerging Trends in the DIN Rail Industry: Revolutionizing Industrial Automation

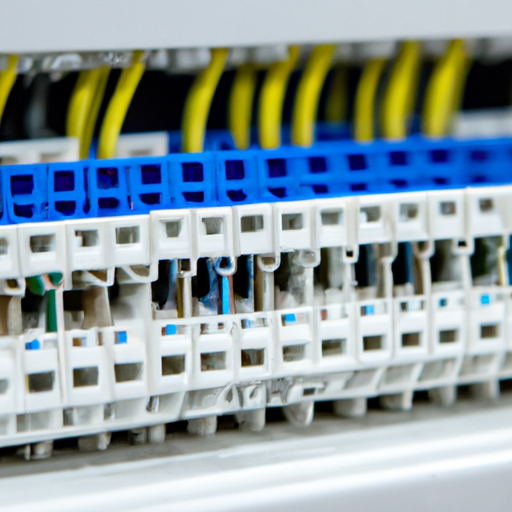

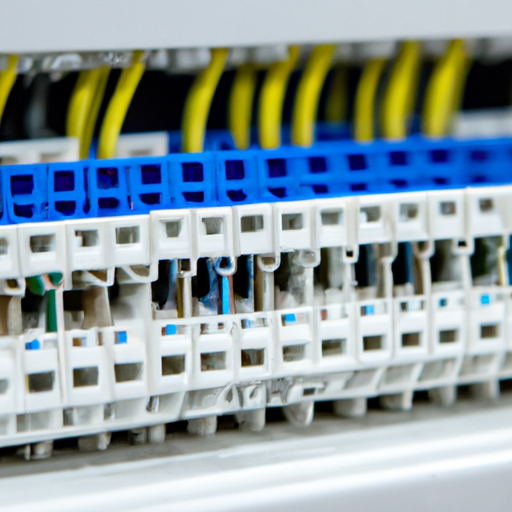

1. Miniaturization and Space Optimization (200 words) One of the prominent trends in the DIN rail industry is the miniaturization of components and devices. As industrial automation systems become more complex, the need for space optimization is crucial. Manufacturers are developing compact DIN rail-mounted devices that offer the same functionality as their larger counterparts. These miniaturized devices not only save valuable space but also reduce installation and maintenance costs.

2. Integration of IoT and Industry 4.0 (250 words) The integration of the Internet of Things (IoT) and Industry 4.0 concepts is revolutionizing the DIN rail industry. IoT-enabled DIN rail devices can collect and transmit real-time data, enabling predictive maintenance, remote monitoring, and enhanced control over industrial processes. This integration allows for improved efficiency, reduced downtime, and increased productivity. Industry 4.0 principles, such as cyber-physical systems and cloud computing, are transforming traditional DIN rail systems into smart, interconnected networks.

3. Increased Demand for Energy Efficiency (200 words) With growing concerns about energy consumption and environmental sustainability, there is a rising demand for energy-efficient DIN rail solutions. Manufacturers are developing devices that consume less power, utilize renewable energy sources, and incorporate energy-saving features. Energy-efficient DIN rail components not only reduce operational costs but also contribute to a greener and more sustainable industrial landscape.

4. Enhanced Safety and Reliability (250 words) Safety and reliability are paramount in industrial automation. The DIN rail industry is witnessing a trend towards the development of devices that meet stringent safety standards and offer enhanced reliability. Manufacturers are incorporating advanced safety features, such as short-circuit protection, overvoltage protection, and fault detection mechanisms, into their DIN rail products. Additionally, the use of high-quality materials and rigorous testing ensures the reliability and durability of these devices, minimizing the risk of system failures and downtime.

5. Customization and Modularization (200 words) To meet the diverse needs of different industries, customization and modularization have become significant trends in the DIN rail industry. Manufacturers are offering a wide range of modular DIN rail components that can be easily configured and combined to create tailored solutions. This flexibility allows for scalability, adaptability, and cost-effectiveness, as businesses can choose and integrate only the necessary modules, reducing unnecessary expenses and simplifying system maintenance.

Conclusion (150 words) The DIN rail industry is experiencing a transformative phase, driven by emerging trends that are revolutionizing industrial automation. Miniaturization, integration of IoT and Industry 4.0, energy efficiency, enhanced safety, and customization are reshaping the industry landscape. These trends offer numerous benefits, including space optimization, improved efficiency, reduced downtime, energy savings, enhanced safety, and tailored solutions. As technology continues to advance, it is crucial for businesses to stay updated with these trends to remain competitive in the rapidly evolving industrial automation sector. By embracing these trends, companies can unlock new opportunities, streamline their operations, and achieve higher levels of productivity and profitability.

Title: Emerging Trends in the DIN Rail Industry: Revolutionizing Industrial Automation

1. Miniaturization and Space Optimization (200 words) One of the prominent trends in the DIN rail industry is the miniaturization of components and devices. As industrial automation systems become more complex, the need for space optimization is crucial. Manufacturers are developing compact DIN rail-mounted devices that offer the same functionality as their larger counterparts. These miniaturized devices not only save valuable space but also reduce installation and maintenance costs.

2. Integration of IoT and Industry 4.0 (250 words) The integration of the Internet of Things (IoT) and Industry 4.0 concepts is revolutionizing the DIN rail industry. IoT-enabled DIN rail devices can collect and transmit real-time data, enabling predictive maintenance, remote monitoring, and enhanced control over industrial processes. This integration allows for improved efficiency, reduced downtime, and increased productivity. Industry 4.0 principles, such as cyber-physical systems and cloud computing, are transforming traditional DIN rail systems into smart, interconnected networks.

3. Increased Demand for Energy Efficiency (200 words) With growing concerns about energy consumption and environmental sustainability, there is a rising demand for energy-efficient DIN rail solutions. Manufacturers are developing devices that consume less power, utilize renewable energy sources, and incorporate energy-saving features. Energy-efficient DIN rail components not only reduce operational costs but also contribute to a greener and more sustainable industrial landscape.

4. Enhanced Safety and Reliability (250 words) Safety and reliability are paramount in industrial automation. The DIN rail industry is witnessing a trend towards the development of devices that meet stringent safety standards and offer enhanced reliability. Manufacturers are incorporating advanced safety features, such as short-circuit protection, overvoltage protection, and fault detection mechanisms, into their DIN rail products. Additionally, the use of high-quality materials and rigorous testing ensures the reliability and durability of these devices, minimizing the risk of system failures and downtime.

5. Customization and Modularization (200 words) To meet the diverse needs of different industries, customization and modularization have become significant trends in the DIN rail industry. Manufacturers are offering a wide range of modular DIN rail components that can be easily configured and combined to create tailored solutions. This flexibility allows for scalability, adaptability, and cost-effectiveness, as businesses can choose and integrate only the necessary modules, reducing unnecessary expenses and simplifying system maintenance.

Conclusion (150 words) The DIN rail industry is experiencing a transformative phase, driven by emerging trends that are revolutionizing industrial automation. Miniaturization, integration of IoT and Industry 4.0, energy efficiency, enhanced safety, and customization are reshaping the industry landscape. These trends offer numerous benefits, including space optimization, improved efficiency, reduced downtime, energy savings, enhanced safety, and tailored solutions. As technology continues to advance, it is crucial for businesses to stay updated with these trends to remain competitive in the rapidly evolving industrial automation sector. By embracing these trends, companies can unlock new opportunities, streamline their operations, and achieve higher levels of productivity and profitability.