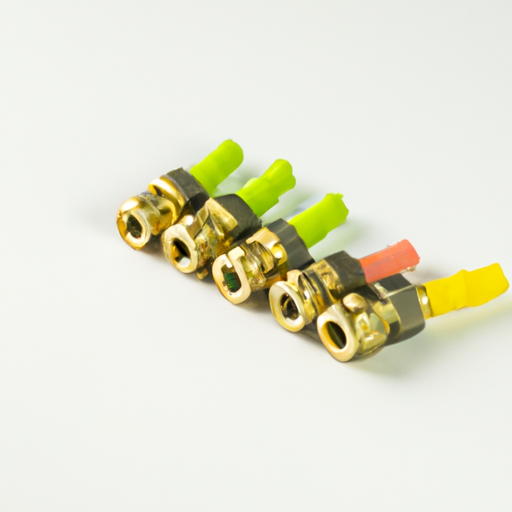

Title: Exploring the Versatile Product Features of Wire Panel Connectors

1. Material Composition and Durability (200 words) Wire panel connectors are typically made from high-quality materials such as stainless steel, aluminum, or galvanized steel. These materials offer exceptional durability, ensuring the connectors can withstand harsh environmental conditions, including extreme temperatures, moisture, and corrosion. The robust construction of wire panel connectors guarantees long-lasting performance, making them suitable for both indoor and outdoor applications.

2. Easy Installation and Assembly (200 words) One of the key features of wire panel connectors is their user-friendly design, which allows for quick and hassle-free installation. These connectors often feature a simple snap-in mechanism or a screw-based system, enabling effortless assembly without the need for specialized tools or expertise. This ease of installation saves time and labor costs, making wire panel connectors an ideal choice for large-scale projects.

3. Versatile Design and Compatibility (250 words) Wire panel connectors come in a variety of designs and sizes, ensuring compatibility with different wire panel types and dimensions. Whether it's mesh panels, wire grids, or fencing panels, these connectors can accommodate various wire thicknesses and configurations. This versatility allows for seamless integration into diverse applications, including industrial enclosures, animal cages, shelving units, and more.

4. Adjustable and Modular Features (250 words) Wire panel connectors often possess adjustable and modular features, enabling customization and adaptability to specific requirements. Some connectors offer adjustable angles, allowing for the creation of curved or angled structures. Additionally, modular connectors can be easily disassembled and reconfigured, providing flexibility in modifying or expanding wire panel systems as needed. This adaptability makes wire panel connectors suitable for dynamic environments where frequent changes or reconfigurations are necessary.

5. Enhanced Safety and Security (200 words) Wire panel connectors play a crucial role in ensuring the safety and security of various applications. These connectors provide a secure connection between wire panels, preventing accidental dislodging or unauthorized access. Additionally, some connectors feature locking mechanisms or tamper-resistant designs, further enhancing security measures. Wire panel connectors are widely used in high-security areas, such as prisons, data centers, and military installations.

6. Aesthetic Appeal and Customization (200 words) Wire panel connectors are not only functional but also contribute to the overall aesthetic appeal of wire panel structures. Manufacturers offer a range of finishes, including powder coating, anodizing, or painting, allowing for customization to match specific design preferences. This feature makes wire panel connectors suitable for architectural applications, such as decorative screens, partitions, and artistic installations.

Conclusion (50 words) Wire panel connectors are versatile products that offer a wide range of features, making them indispensable in various industries. From their durable construction to easy installation, compatibility, adjustability, and enhanced safety, these connectors provide numerous benefits. Their ability to combine functionality with aesthetic appeal makes wire panel connectors a valuable asset in modern construction and design.

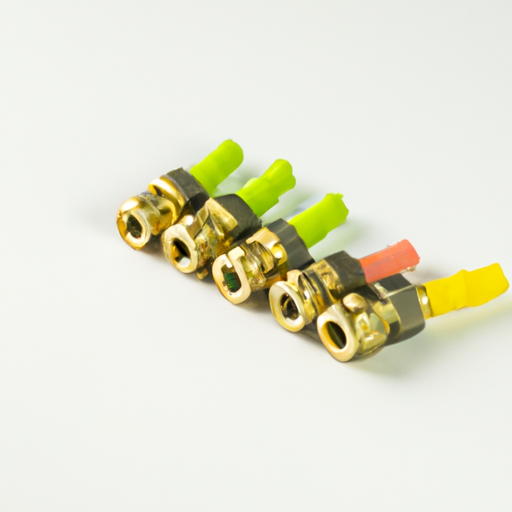

Title: Exploring the Versatile Product Features of Wire Panel Connectors

1. Material Composition and Durability (200 words) Wire panel connectors are typically made from high-quality materials such as stainless steel, aluminum, or galvanized steel. These materials offer exceptional durability, ensuring the connectors can withstand harsh environmental conditions, including extreme temperatures, moisture, and corrosion. The robust construction of wire panel connectors guarantees long-lasting performance, making them suitable for both indoor and outdoor applications.

2. Easy Installation and Assembly (200 words) One of the key features of wire panel connectors is their user-friendly design, which allows for quick and hassle-free installation. These connectors often feature a simple snap-in mechanism or a screw-based system, enabling effortless assembly without the need for specialized tools or expertise. This ease of installation saves time and labor costs, making wire panel connectors an ideal choice for large-scale projects.

3. Versatile Design and Compatibility (250 words) Wire panel connectors come in a variety of designs and sizes, ensuring compatibility with different wire panel types and dimensions. Whether it's mesh panels, wire grids, or fencing panels, these connectors can accommodate various wire thicknesses and configurations. This versatility allows for seamless integration into diverse applications, including industrial enclosures, animal cages, shelving units, and more.

4. Adjustable and Modular Features (250 words) Wire panel connectors often possess adjustable and modular features, enabling customization and adaptability to specific requirements. Some connectors offer adjustable angles, allowing for the creation of curved or angled structures. Additionally, modular connectors can be easily disassembled and reconfigured, providing flexibility in modifying or expanding wire panel systems as needed. This adaptability makes wire panel connectors suitable for dynamic environments where frequent changes or reconfigurations are necessary.

5. Enhanced Safety and Security (200 words) Wire panel connectors play a crucial role in ensuring the safety and security of various applications. These connectors provide a secure connection between wire panels, preventing accidental dislodging or unauthorized access. Additionally, some connectors feature locking mechanisms or tamper-resistant designs, further enhancing security measures. Wire panel connectors are widely used in high-security areas, such as prisons, data centers, and military installations.

6. Aesthetic Appeal and Customization (200 words) Wire panel connectors are not only functional but also contribute to the overall aesthetic appeal of wire panel structures. Manufacturers offer a range of finishes, including powder coating, anodizing, or painting, allowing for customization to match specific design preferences. This feature makes wire panel connectors suitable for architectural applications, such as decorative screens, partitions, and artistic installations.

Conclusion (50 words) Wire panel connectors are versatile products that offer a wide range of features, making them indispensable in various industries. From their durable construction to easy installation, compatibility, adjustability, and enhanced safety, these connectors provide numerous benefits. Their ability to combine functionality with aesthetic appeal makes wire panel connectors a valuable asset in modern construction and design.