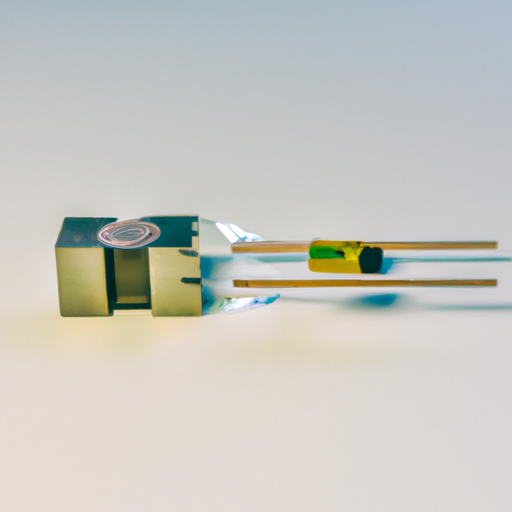

Vibration sensor products play a crucial role in a wide range of practical applications across various industries. These sensors are designed to detect and measure vibrations in machinery, structures, and other systems, providing valuable data that can be used for monitoring, maintenance, and safety purposes. In this article, we will explore the importance of vibration sensor products in practical applications and how they are used in different industries.

In manufacturing plants, vibration sensors are used to monitor the condition of rotating equipment such as motors, pumps, compressors, and turbines. By detecting changes in vibration levels, these sensors can help identify issues such as bearing wear, misalignment, and unbalance, allowing maintenance teams to schedule repairs before equipment fails. This proactive approach to maintenance, known as predictive maintenance, can help reduce downtime, extend equipment life, and optimize production processes.

In the automotive industry, vibration sensors are used in vehicles to monitor the condition of critical components such as engines, transmissions, and suspension systems. These sensors can detect abnormal vibrations that may indicate issues such as engine misfires, worn bearings, or unbalanced tires. By alerting drivers or service technicians to potential problems, vibration sensors can help prevent accidents, improve vehicle performance, and reduce maintenance costs.

In the aerospace industry, vibration sensors are used to monitor the structural health of aircraft, spacecraft, and other aerospace systems. These sensors can detect vibrations caused by factors such as turbulence, engine vibrations, and structural fatigue, allowing engineers to assess the integrity of critical components and make informed decisions about maintenance and repairs. By monitoring vibrations in real-time, aerospace companies can ensure the safety and reliability of their vehicles, comply with regulatory requirements, and minimize the risk of catastrophic failures.

In the construction industry, vibration sensors are used to monitor the structural integrity of buildings, bridges, and other infrastructure projects. These sensors can detect vibrations caused by factors such as wind, traffic, construction activities, and seismic events, allowing engineers to assess the stability of structures and identify potential risks. By monitoring vibrations over time, construction companies can ensure that their projects meet safety standards, comply with building codes, and withstand environmental challenges.

Overall, vibration sensor products play a critical role in practical applications across various industries by providing valuable data that can be used to monitor, maintain, and optimize equipment and structures. By detecting and analyzing vibrations, these sensors help improve the reliability, efficiency, and safety of systems, leading to cost savings, increased productivity, and enhanced performance. As technology continues to advance, the demand for vibration sensor products is expected to grow, driving innovation and new applications in industries around the world.

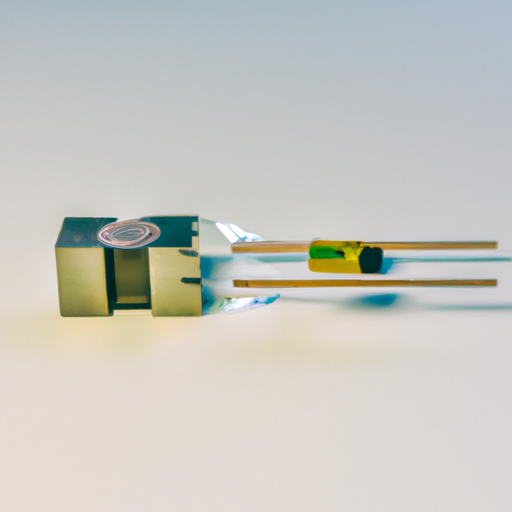

Vibration sensor products play a crucial role in a wide range of practical applications across various industries. These sensors are designed to detect and measure vibrations in machinery, structures, and other systems, providing valuable data that can be used for monitoring, maintenance, and safety purposes. In this article, we will explore the importance of vibration sensor products in practical applications and how they are used in different industries.

In manufacturing plants, vibration sensors are used to monitor the condition of rotating equipment such as motors, pumps, compressors, and turbines. By detecting changes in vibration levels, these sensors can help identify issues such as bearing wear, misalignment, and unbalance, allowing maintenance teams to schedule repairs before equipment fails. This proactive approach to maintenance, known as predictive maintenance, can help reduce downtime, extend equipment life, and optimize production processes.

In the automotive industry, vibration sensors are used in vehicles to monitor the condition of critical components such as engines, transmissions, and suspension systems. These sensors can detect abnormal vibrations that may indicate issues such as engine misfires, worn bearings, or unbalanced tires. By alerting drivers or service technicians to potential problems, vibration sensors can help prevent accidents, improve vehicle performance, and reduce maintenance costs.

In the aerospace industry, vibration sensors are used to monitor the structural health of aircraft, spacecraft, and other aerospace systems. These sensors can detect vibrations caused by factors such as turbulence, engine vibrations, and structural fatigue, allowing engineers to assess the integrity of critical components and make informed decisions about maintenance and repairs. By monitoring vibrations in real-time, aerospace companies can ensure the safety and reliability of their vehicles, comply with regulatory requirements, and minimize the risk of catastrophic failures.

In the construction industry, vibration sensors are used to monitor the structural integrity of buildings, bridges, and other infrastructure projects. These sensors can detect vibrations caused by factors such as wind, traffic, construction activities, and seismic events, allowing engineers to assess the stability of structures and identify potential risks. By monitoring vibrations over time, construction companies can ensure that their projects meet safety standards, comply with building codes, and withstand environmental challenges.

Overall, vibration sensor products play a critical role in practical applications across various industries by providing valuable data that can be used to monitor, maintain, and optimize equipment and structures. By detecting and analyzing vibrations, these sensors help improve the reliability, efficiency, and safety of systems, leading to cost savings, increased productivity, and enhanced performance. As technology continues to advance, the demand for vibration sensor products is expected to grow, driving innovation and new applications in industries around the world.