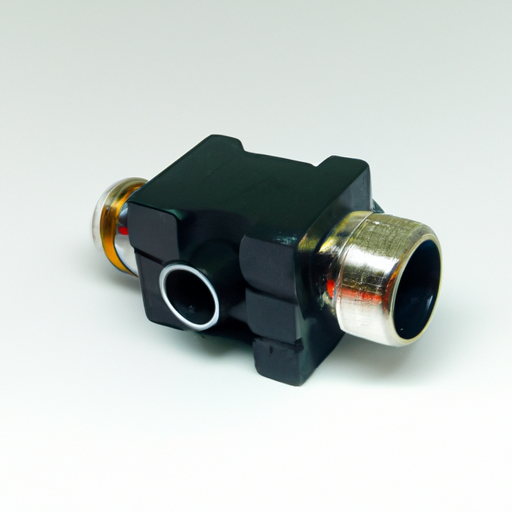

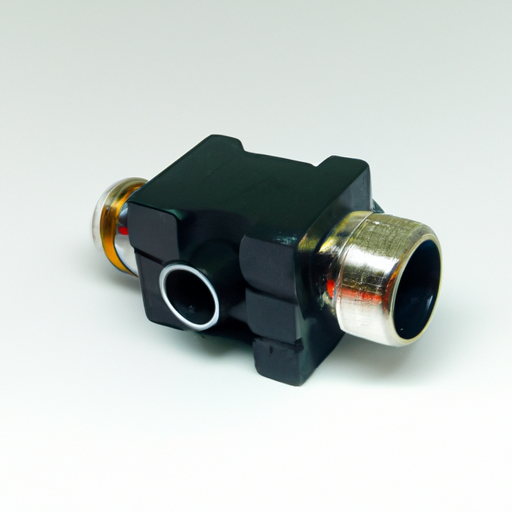

Position sensor products are essential components in a wide range of industries, from automotive to aerospace, robotics to medical devices. These sensors play a crucial role in measuring the position of an object or system, providing valuable data that can be used for control, monitoring, and feedback purposes. In this article, we will explore the advantages of position sensor products and how they contribute to the efficiency, accuracy, and safety of various applications.

2. Real-time Monitoring: Position sensor products offer real-time monitoring capabilities, allowing operators to track the position of an object or system continuously. This real-time feedback is essential for applications where precise control is required, such as in industrial automation, where sensors are used to monitor the position of conveyor belts, robotic arms, and other moving parts. By providing instant feedback on the position of these systems, position sensor products help operators identify and address any issues quickly, minimizing downtime and improving overall efficiency.

3. Increased Productivity: Position sensor products can help increase productivity by automating repetitive tasks and streamlining processes. For example, in manufacturing environments, sensors are used to monitor the position of workpieces on assembly lines, ensuring that they are correctly positioned for each operation. By automating these tasks, manufacturers can reduce the risk of errors and improve production efficiency, leading to higher output and lower costs.

4. Improved Safety: Position sensor products play a crucial role in ensuring the safety of workers and equipment in various industries. For example, in automotive applications, sensors are used to monitor the position of airbags, seat belts, and other safety systems, ensuring that they deploy correctly in the event of a collision. In industrial settings, sensors are used to monitor the position of heavy machinery and equipment, helping to prevent accidents and injuries. By providing real-time feedback on the position of these systems, position sensor products help operators identify potential safety hazards and take corrective action before an incident occurs.

5. Versatility and Flexibility: Position sensor products are available in a wide range of types and configurations, making them versatile and adaptable to a variety of applications. Whether you need a linear position sensor for measuring the position of a moving object in a straight line or a rotary position sensor for monitoring the angle of rotation of a shaft, there is a sensor available to meet your specific requirements. Additionally, position sensor products can be easily integrated into existing systems, making them a cost-effective solution for upgrading and enhancing the functionality of equipment.

6. Cost-effective Solution: Position sensor products offer a cost-effective solution for measuring position in a wide range of applications. Compared to traditional methods of position measurement, such as manual measurement or mechanical switches, sensors are more accurate, reliable, and efficient. By using position sensor products, manufacturers can reduce the risk of errors, minimize downtime, and improve overall productivity, leading to cost savings in the long run.

In conclusion, position sensor products offer a wide range of advantages for various industries, including precision and accuracy, real-time monitoring, increased productivity, improved safety, versatility, flexibility, and cost-effectiveness. By using position sensor products, manufacturers can enhance the efficiency, accuracy, and safety of their systems, leading to improved performance and reduced costs. Whether you are in the automotive, aerospace, robotics, or medical device industry, position sensor products are essential components that can help you achieve your goals and stay ahead of the competition.

Position sensor products are essential components in a wide range of industries, from automotive to aerospace, robotics to medical devices. These sensors play a crucial role in measuring the position of an object or system, providing valuable data that can be used for control, monitoring, and feedback purposes. In this article, we will explore the advantages of position sensor products and how they contribute to the efficiency, accuracy, and safety of various applications.

2. Real-time Monitoring: Position sensor products offer real-time monitoring capabilities, allowing operators to track the position of an object or system continuously. This real-time feedback is essential for applications where precise control is required, such as in industrial automation, where sensors are used to monitor the position of conveyor belts, robotic arms, and other moving parts. By providing instant feedback on the position of these systems, position sensor products help operators identify and address any issues quickly, minimizing downtime and improving overall efficiency.

3. Increased Productivity: Position sensor products can help increase productivity by automating repetitive tasks and streamlining processes. For example, in manufacturing environments, sensors are used to monitor the position of workpieces on assembly lines, ensuring that they are correctly positioned for each operation. By automating these tasks, manufacturers can reduce the risk of errors and improve production efficiency, leading to higher output and lower costs.

4. Improved Safety: Position sensor products play a crucial role in ensuring the safety of workers and equipment in various industries. For example, in automotive applications, sensors are used to monitor the position of airbags, seat belts, and other safety systems, ensuring that they deploy correctly in the event of a collision. In industrial settings, sensors are used to monitor the position of heavy machinery and equipment, helping to prevent accidents and injuries. By providing real-time feedback on the position of these systems, position sensor products help operators identify potential safety hazards and take corrective action before an incident occurs.

5. Versatility and Flexibility: Position sensor products are available in a wide range of types and configurations, making them versatile and adaptable to a variety of applications. Whether you need a linear position sensor for measuring the position of a moving object in a straight line or a rotary position sensor for monitoring the angle of rotation of a shaft, there is a sensor available to meet your specific requirements. Additionally, position sensor products can be easily integrated into existing systems, making them a cost-effective solution for upgrading and enhancing the functionality of equipment.

6. Cost-effective Solution: Position sensor products offer a cost-effective solution for measuring position in a wide range of applications. Compared to traditional methods of position measurement, such as manual measurement or mechanical switches, sensors are more accurate, reliable, and efficient. By using position sensor products, manufacturers can reduce the risk of errors, minimize downtime, and improve overall productivity, leading to cost savings in the long run.

In conclusion, position sensor products offer a wide range of advantages for various industries, including precision and accuracy, real-time monitoring, increased productivity, improved safety, versatility, flexibility, and cost-effectiveness. By using position sensor products, manufacturers can enhance the efficiency, accuracy, and safety of their systems, leading to improved performance and reduced costs. Whether you are in the automotive, aerospace, robotics, or medical device industry, position sensor products are essential components that can help you achieve your goals and stay ahead of the competition.